The Woodturners Sharpening Disc

Sharpening and hone your turning tools with this

Introduction and Pictures

This article is about what I mainly use to sharpen and hone. I don't grind on this. Here's a really short description on my philosophy on the whole matter.

I Grind only new tools that aren't the correct profile for my needs or if I've really messed up a tool by dropping it or letting an apprentice or student practice sharpening with it.

I Sharpen a tool when it's really quite dull and doesn't respond to honing.

I Hone more than half the time I'm not turning wood. I keep the tool sharpest this way and spend less time, overall, not turning wood.

Here's more on the subject ...

I GRIND (I call it "profiling" too) on a highspeed grinder with 2" wide silicon carbide (yes, those grey ones that most woodturners throw away immediately except these are high quality and very wide) wheels. For the lifespan of my typical tools, I grind/profile about 5% of the time.

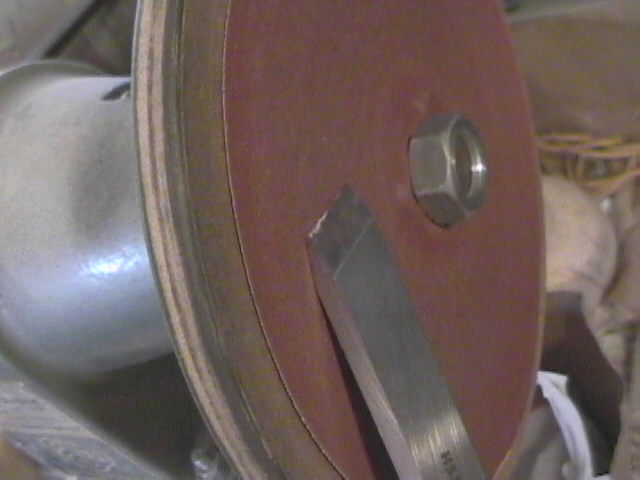

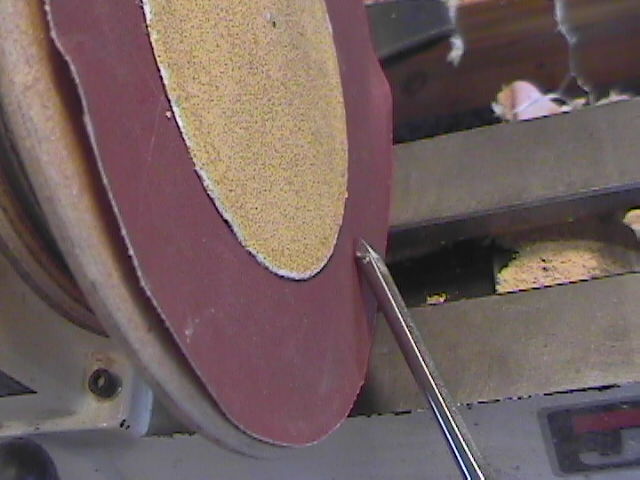

I SHARPEN on these sanding disks against the sandpaper (the red/rust colored stuff in the pictures) side. The sandpaper shown in these pictures is the regular aluminum oxide used to cut wood. I have since switched to silicon carbide sandpaper as it's designed to cut metal, stays cooler and it lasts longer. I sharpen maybe 40% of the time.

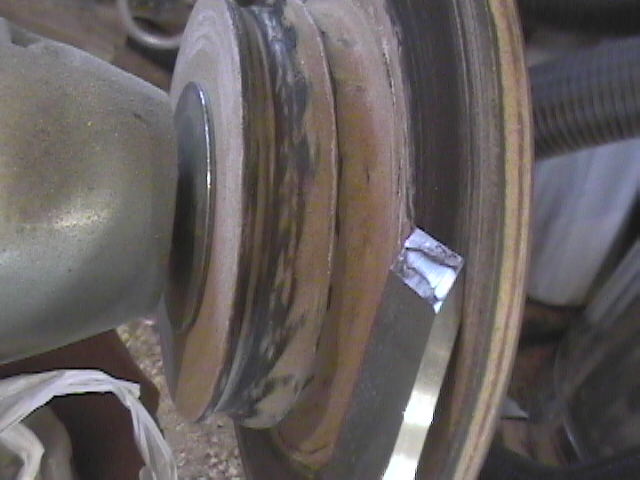

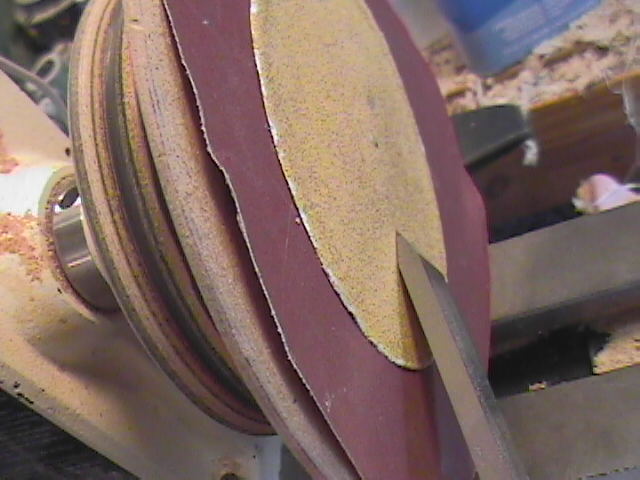

I HONE on the backside and rims of these sanding disks. The black is where the metal is coming off of the tools as I hone. These sanding disks are profiled with straight sections, coves and beads of different sizes to match the woodturning tools I use on them. I hone the rest of the time.

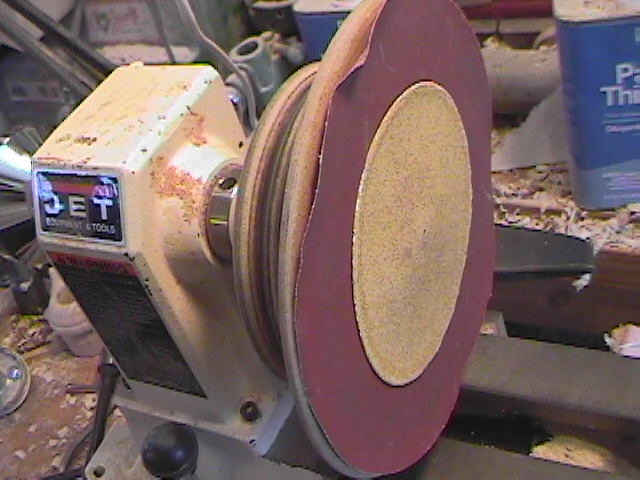

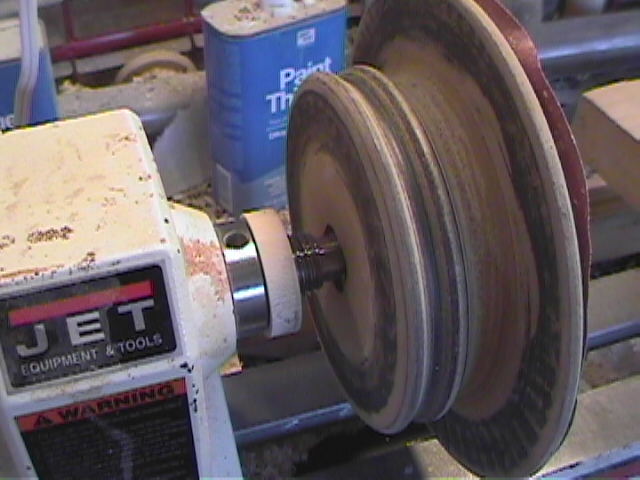

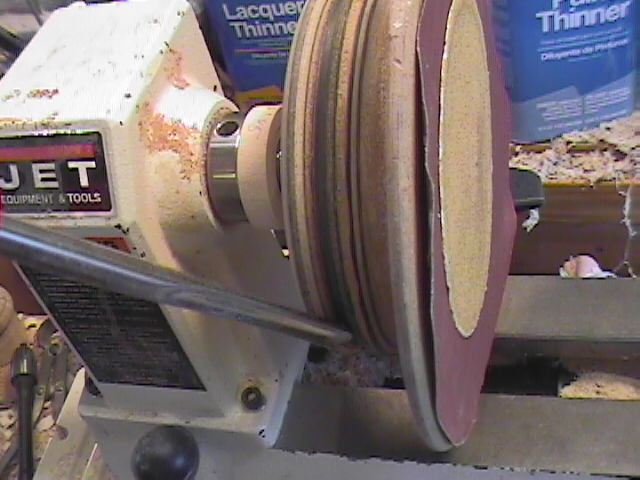

In the above pictures, you'll see 2 different setups. The first set is of the large sanding disk that I have mounted on an arbor connected to a 1 hp motor by belt. The other side of the arbor is a grinding wheel. This is my main in-shop tool maintenance area and I keep it running at all times when I'm working on the lathe. It's stands right next to my lathe so that I'm just one step away from it. I usually don't even change my hand position on the tool from the lathe to the grinding/sharpening/honing station and back again to the lathe. It just takes a few seconds to sharpen or hone and I'm back to work. The second set of pictures is of the smaller travel version that I take with me to demonstrations and events. This way, I don't have to lug around any sharpening equipment and/or use someone elses'. It has a morse taper on one side that I just stick into the wood lathe when I need to do touchups if needed. If I have to hone a little during a project, I'll usually just use a diamond paddle instead of taking the piece off the lathe to put the sharpening disk on and etc.

You'll notice in these pictures that I don't use jigs to grind/sharpen/hone. I don't have a toolrest either. Not even on the unpictured grinding wheel. I do everything freehand ... and I do mean freehand. It's not for everyone (although I don't see why they couldn't ... I can do it after all) but it works for me and is so very versatile and inexpensive. Practice practice practice ... just like lathe-work, eh?

Please note: Direction of the spinning disk is very important! The large in-shop one spins "away" from me. That's why the tools are presented in the direction that they are. The one mounted to the lathe runs "toward" me and is why those tools are presented they way they are. YES, I do forget when switching from one to the other. But I do it only once before I get woken up! The sandpaper and MDF WILL catch if you get an edge from the tool in them. So watch it.

These sanding disks are just made from 3 glued-up layers of MDF (Medium Density Fiberboard). You can get it at most major home centers/hardware stores. It's heavy and it's somewhat costly when compared to plywood. DO NOT USE PLYWOOD! It'll fly apart and not do a good job at all anyway. Don't get MDF wet either. It'll disintegrate and bulge, becoming useless.

I attach the sandpaper to the MDF with just spray adhesive. The sandpaper comes away from the MDF a little if I don't use it for awhile but it lays back down as soon as you use it again. Otherwise, just use some more spray adhesive. Not so much that you get runs though. The sandpaper grit I use most is 100 grit. You can also put another, smaller, piece of sandpaper on there for 2 grits to use (bottom photos). One is usually sufficient though. For the honing (backside of the sanding disk) area, I use a white diamond honing compound. Just rub a bit on the spinning disk and it stays there for a long time.

I figured that the total cost of one of these disks was less than around $10-15US. If you're interested in buying a video (DVD or Tape) on the sharpening disc and sharpening woodturning tools in general, we made one!